What equipment is needed for a mini-printing house

Currently, the development of technology for printing houses has moved to a new quality level. A modern multifunctional printing house can be located in a small office and solve the whole range of tasks set by customers. The speed of order fulfillment, its quality, the speed of restructuring and adjusting the equipment with small order volumes - all this is the hallmark of the modern small printing business.

As you know, "advertising is the engine of trade", the intensive development of small business in Russia forms a team of customers for small printing houses. In this article, the authors have tried to describe the necessary units for creating a mini-printing house, as well as specialized complexes necessary for the further development of the enterprise.

Printing complexes and related units for small printing houses.

At the first stage, it is necessary to decide on the production facility and begin equipping it with equipment.

The mini-typography format assumes the use of the following technical devices:

- To reduce the printing time for A4 sheets, you must have an A3 risograph. Two A4 sheets are placed on the A3 sheet area. The optimal printing speed of the risograph is in the range from 60 to 130 pages per minute.

- To obtain high-quality copies of A3 and A4 size, you need a copier with a print speed of about 15 A3 sheets per minute. Replaceable equipment for it: toner for printing 3,000 A3 pages and a photo drum with a resource of 100,000 copies.

- To print text or images in digital format, you need a color laser printer with a print speed of about 8 sheets per minute and a 7,500 sheet photo drum resource.

- To convert images into digital format, you need a scanner with a scanning window size of 216x279 mm, and capable of transmitting an image for printing to a printer without additional devices.

With a limited budget, all this equipment can be bought on the secondary market in good condition.

Equipment manufacturers recommend original consumables for their devices. For a risograph you need a master film, for a printer and a copier - a replaceable photo drum. To fulfill orders, you should stock up on A4 and A3 paper.

Installations for printing in a printing house

Promotion of goods and services of commercial companies requires a large variety of printed materials. Full-fledged printing plants provide a full range of services for commercial printed products.

List of required printing machines

- The most optimal ratio of price to quality of goods is ensured by a printing installation that uses the technology of applying an image using offset printing. This technology allows you to print small and not very large runs, providing good quality. The principle of operation of the equipment is based on the transfer of the image from the offset shaft to the printing shaft. The equipment cost is affordable for small businesses.

- The hydraulic paper cutter cuts high quality paper in various sizes at a minimum cost. This cutter will allow you to cut high quality 30,000 copies.

- In the printing business, there is a special folding machine for breaking up and forming a multi-page brochure. There are a large number of equipment for performing the folding operation, each with its own unique specifics. At the stage of formation of the printing house, there will be enough machine to create multi-page brochures.

Typographic installations provided in this list cost around 2 million rubles. The operation of this equipment can provide a city district or a large district center with printed products.

Types of printing

Advertising printed materials, made in the style of the company, personify the reliability and presentability of the organization. The quality of printing, paper, professional design is the key to the success of the advertising campaign. There are several types of printing, each type has its own advantages and disadvantages. Choosing the right type of print will determine the cost of the print run and its quality.

Screen printing

This method can be applied to the image not only on paper, but also on the surface of metal, fabric, glass or ceramics. The second name for this printing method is silk screen printing. Through silk-screen printing, you can get volumetric, embossed images. Offset printing is inferior to screen printing in color saturation. Silkscreen printing technology makes it possible to use more ink materials. When creating relief images, a special powder is used, when melted, colorful reliefs on the surface are delighted.

Embossing

This printing method is beneficial for very large print runs. It allows you to print large quantities at a good speed and while maintaining high quality. For printing from metal or plastic, a cliché is created, a beautiful embossed image is formed during printing, and the surface of paper or leather can be metallized with foil. The image takes on a unique design and a rich, solid look.

Digital printing

The advantages of such printing are the speed of equipment restructuring, prompt changes in the layout of the printed image, speed and simplicity of the process. This method is indispensable for the production of small and small runs.

Disadvantages of this method: the impossibility of obtaining unique colors and shades, it is difficult to apply the image on textured paper, gaps are formed, the average quality of image printing.

Gravure printing

This is one of the varieties of embossed printing. Screen gravure printing is created by rolling or imprinting the matrix on the working surface. The impression cylinder can be engraved in various ways: mechanical, chemical etching or laser. From the place on the cylinder where the image should not be present material is selected. Excess ink that enters the groove is removed with a squeegee. One type of this seal is used to make money. The most expensive part of this type of printing is the matrix on which the image is engraved. It is made of durable material and is enough for a very large number of images.

Typically, this type of printing is used for printing on packaging and is cost-effective for very large runs.

Flexography

To apply the image on flexible carriers or corrugated surface: plastic bags, cardboard with corrugated structure, a subspecies of rotary printing - flexography - was developed.The impression matrix is made of flexible materials and allows you to apply high-quality images on various materials and complex surfaces. Basically, fast-drying paints are used to apply the image. The production of a printing plate is cheaper than with gravure printing, and, accordingly, this method pays off in much smaller print runs.

Offset printing

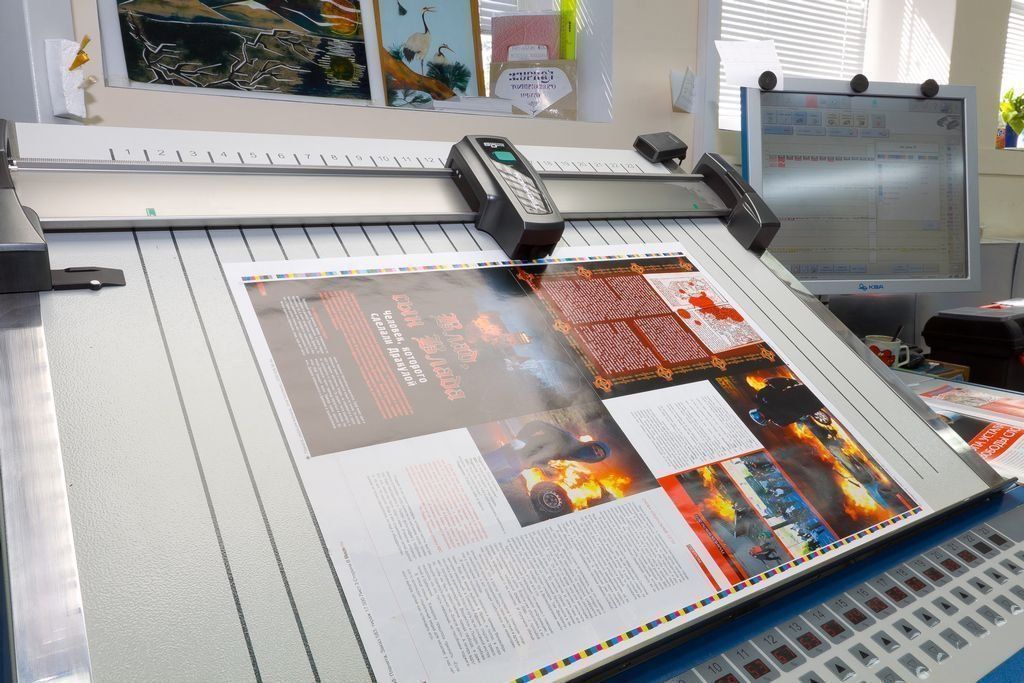

Modern printing equipment working on offset printing technology is the most popular and widespread.

The technology for applying the image is divided into several technological operations. Through a tuned stencil, the image is projected onto an offset roller, the roller coating selectively attracts ink, depending on whether the cylinder section is illuminated or darkened. The illuminated parts of the shaft repel the paint, and the dark ones, on the contrary, attract. Then the image applied from the stencil is transferred from the offset shaft to the printing one, and printing on the prepared paper takes place.

To print multi-colored images, sequential application of ink of different colors using the CMYK system is used. After drawing the image onto the paper, the ink is washed off the rollers with water.

Due to the fact that it takes a lot of time to set up a printing unit before each print, it is not cost-effective to print small batches of products on it.

In order to speed up the printing of color images, it is better to use inks that dry quickly under the influence of ultraviolet rays.

Tools and equipment for creating books and brochures

The cost of printed products and their competitive advantages strongly depend on the time spent on auxiliary processes: adjustment and adjustment of equipment, production of matrices, but manufacturers bear no less costs to create the final product. After applying an image to the sheet, it is necessary to create a product demanded by the consumer. Several types of machines have been developed to create printed products.

Equipment types required to create the final product

A paper cutter, cuts advertising materials, posters, calendars exactly to size.

Installation of metal stapling of sheets for the formation of brochures. The unit makes metal brackets of the required size according to a given program. Without this equipment, it is impossible to make some samples of printed products. This setting is used in most medium-sized printing houses.

Large printing houses use folding machines and embossing machines to make books and magazines. The book consists of a series-connected set of notebooks, forms notebooks from printed sheets of a folding installation. There are various types of machines: knife, cassette or combined.

Large printing plants are equipped with unique installations: thermal binding, stitching, die-cutting and collating. They use automated quality control systems to compare the received product with a reference sample and reject substandard goods.

The development and improvement of printing units makes manufacturers strive to improve the facilities for the production of full-fledged books and illustrated magazines.

World leaders in the production of printing equipment

Below are the popular models from global manufacturers.

Installations providing preparatory processes

Esko-Graphics has unveiled the latest third generation model of its PlateDriver 8, the first generation CtP, with FlowDrive process control. This equipment is necessary for full-cycle printing plants and is aimed at producing high-quality, commercial printed products.

For the production of metal molds with a layer of photosensitive material, FUJIFILM has developed a set of Luxel V8 equipment in the CtP format. The achievable resolution of the machine is 3670 dpi. This setting is in demand in printers using sheet aggregates to create advertisements.

Printing equipment

The printing system of the new generation KOMORI LITHRONE S40 is distinguished by full automation of all processes, very high-quality printing and high speed of process changeovers. Designed for commercial printing applications, this system offers increased reliability, performance and durability.

KBA has developed a modern PERFORMA 74-5 five-color offset press. The design of the machine guarantees high print quality, has its own quality control system KBA Control, and is provided with an instant ink drying system.

Equipment for creating books and brochures

The modern, fully automated folding machine GUK 54/6 KL-R6 is built on the principle of "open architecture" and has a modular structure. The consumer independently chooses a set of modules necessary for his work. The design of the machine consists of a strong base and a modern, highly efficient drive, ensuring high reliability of the unit. A distinctive feature of this installation is ease of operation and high productivity.

No matter how the world and the options for providing data have changed, the main source of information has always been and will be printed matter. Books will make leisure more useful and enjoyable, they have become a source of discussion, thanks to them, a worldview is formed, an idea of good and bad. The right of the printing industry to exist today has been proven, and it occupies a leading position in a number of sources of information.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95021 -

Rating of cheap analogues of expensive medicines for flu and colds for 2020

Views: 91750 -

The best men's running shoes in 2020

Views: 87680 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77201 -

Ranking of the best action cameras from China in 2020

Views: 75268 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72462 -

Top rating of the best means for male potency in 2020 with a description

Views: 68295