Ranking of the best touch panel controllers for 2020

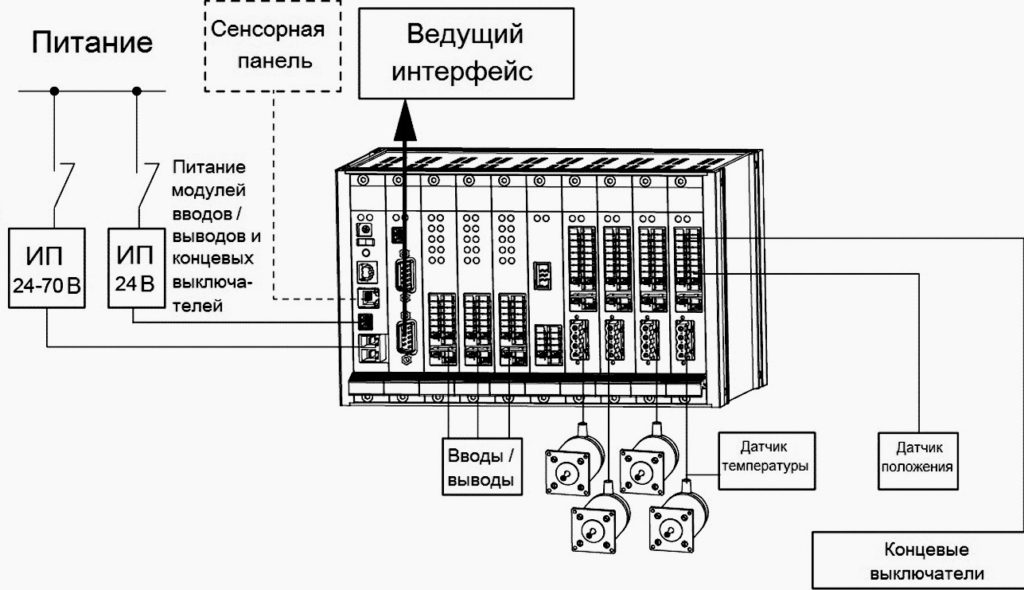

Often, a person interacts with automation through operator panels, which receive, process and transmit information. Typically, it is associated with one or more controllers. Almost all areas of industry are equipped with such devices. It is programmed for specific human-controlled equipment. At the same time, the operator must easily cope with the assigned tasks, and the design must be very convenient to quickly start the work process, monitor the operation of equipment, save data, etc.

Moreover, the operator panel makes it possible to identify equipment malfunctions, prevent the possibility of an emergency and minimize damage. Control of such modern equipment is carried out through the selected interface, which significantly increases its efficiency and productivity indicator. Today, this type of structure can be found not only in production workshops, but also in private houses. We are talking about smart home systems and devices serviced by housing and communal enterprises.

What it is

The use of the operator panel allows you to combine the functionality of simpler signal and control devices. Controllers and panels are interconnected by means of interface cables. Through the interaction of devices with each other, the panel will display the current data regarding the state and operation of the equipment. All data is updated periodically and transmitted to the console in real time.

The presence of the panel makes it possible to eliminate the need to install various indicators, buttons, switches, displays, which saves a lot of free space. It turns out: a multifunctional remote control takes up a minimum of free space, so there are many convenient places where it can be installed.

It should be noted that the main panel has IP protection. The device consists of a number of key elements, including:

- There are several types of display. The most commonly used test-graphic, test or graphic.

- Input device. It is a touch screen, keyboard and joystick for more convenient operation.

- Internal memory that can be supplemented with a memory card.

- Programmable logic controller. Not all models are equipped with such a device.

- Interface. It is used both for communication with external control devices and for programming.

- Specialized software.

Today the market is full of various devices offered by the best manufacturers.They differ in average price, characteristics, functionality, settings, material of manufacture and other aspects.

Despite this variety, all operator panels are of the following types:

| A type | Short description |

|---|---|

| Sensory | There is a real opportunity for operators to show their creative imagination, creating unique graphic elements, as well as screens with a set of specific functions. The ability to download custom graphics. It is controlled by an active matrix of the screen that reacts to touch. |

| Graphic | Equipped with a keypad with buttons that have individual meaning. There is a group of specific screens where graphs and diagrams are displayed. They are widely used in industry. |

| Sensory logic | Their main design feature is the presence of a built-in programmed logic controller, which makes it possible to create the program itself in one device and visualize it there. |

| Test - graphical, equipped with a keyboard | Similar to the units of the graphic type category. They are very popular in the industrial sector. |

General information on touch panel controllers

Touch devices are classified as budget controllers. They are modern equipment that is applicable to the class of human-machine interface.

Available recommendations:

- ITP and TSC;

- management of refrigeration units, incubators, heat chambers and other climatic devices;

- application in water intake systems;

- installation in ventilation systems;

- installation on the territory of boiler houses;

- on conveyors, machine tools and other automated installations of local type;

- mobile and remote systems.

It should be noted that there is a built-in function that allows you to program the unit. It is used to create an automated control system in the power industry (technological processes), housing and communal services and other industrial areas of activity.

Distinctive characteristics:

- run on an operating system such as Linux;

- the ability to directly work with other controller ports (allows you to connect devices that have a non-standard interface or type);

- operating exchange protocols - ARIES, ModBus (ASCII, RTU);

- touch screen control;

- built-in clock showing real time;

- the ability to switch operating modes at the software level when using universal interfaces (RS-232 / RS-485);

- the case may contain a PLC and a graphic operator panel;

- on the front panel, you can find a place intended for connecting to the network;

- The Internet access does not work;

- application of a unified programming environment for control algorithms and work with visualization programs;

- its own memory, which can be expanded if necessary.

The lineup has the following characteristics:

- Protection degree - IP.

- Temperature range - from 0 to +60 degrees.

- Voltage - 12 to 28 V.

- Power - maximum 10 watts.

- The body and front panel are made of durable plastic.

- Cooling is passive.

Operating rules:

- It is necessary to observe an acceptable temperature regime in the room.

- Rooms and cabinets must belong to the highest explosion-proof category. The presence of gases and aggressive vapors is categorically unacceptable.

- There must be no moisture condensation. The maximum indicator of air humidity at a temperature of +25 degrees is from 10 to 90%.

- The atmospheric pressure limit is from 84 to 106.7 kPa.

Design features:

- The device panel is made in the form of a shield. Popular manufacturers produce their own models that vary in functionality and size.

- To expand the number of points for output and input, you will need an auxiliary module (external) for each of the interfaces used.

How to choose

The answer to this question depends on the direction of use of the product and the user's preferences. There is no single selection criterion.Every year, global manufacturers of this type of product introduce the public to popular models. The new items produced have both some advantages and tangible disadvantages. They differ in cost, functionality, as well as options and characteristics. Before purchasing a device, it is recommended that you familiarize yourself with the rating of quality products, understand what they are.

What is a PLC for? To determine which company has the best products. Have the ability to correlate data with customer opinions as well as user reviews. What to pay special attention to in order to avoid mistakes when choosing? On the operating system parameters. There is a tangible difference between serving a large enterprise and a small production.

It is not at all a difficult question where to buy a quality product. Today there are many retail outlets that offer their customers high quality products with a guarantee. The product can be ordered online in the online store. This will allow you not only to save money, but also to get a quality product directly from the manufacturer.

The only limitation is that you cannot make such a product with your own hands at home. Even step-by-step instructions will not help here, since equipment of this type belongs to the category of high-precision and requires special equipment in the manufacture, which is unlikely to be found in the house. However, if you have some experience and knowledge, you can install the panel yourself.

Ranking of the best touch panel controllers for 2020

Panel Controllers for Local System Automation with Ethernet

SPK107

An excellent product that is a logical continuation of the SPK1xx line. High quality product from a renowned domestic brand. An initial review showed improved performance. The software has also undergone some updates. This made it possible to use this type of equipment in industrial enterprises that need to automate the work process. The number of points of outputs and inputs can be increased, but this will require the purchase of auxiliary modules for each of the interfaces used.

The product is equipped with DB9-terminal adapters with built-in 120 Ohm terminating resistors connected by DIP switches. The manufacturer has developed a device with full compatibility with previously released modifications. Provides direct connection via USB-A port — mouse, keyboard.

The model is applied:

- HVAC systems;

- Housing and communal services;

- water utilities (ACS);

- for the purpose of programming equipment;

- in the process of manufacturing building materials;

- for ease of control of climatic equipment.

Codesys V 3.5 is used - an optimal programming environment that complies with the current IEC standard IEC 61131-3. The unit supports five programming languages, which will allow specialists of any profile to work with it.

General characteristics:

- estimated frequency - 600 MHz;

- the amount of flash memory - 4096 MB;

- RAM - 512 MB;

- non-volatile real time clock is present;

- display type - TFT LCD;

- backlight - LED;

- brightness - 300 cd / m2;

- no galvanic isolation;

- food - constant;

- voltage - from 12 to 28 V;

- power consumption - 5 W;

- ventilation - natural;

- dimensions - 204 x 149 x 37mm;

- the average service life is 12 years.

In addition to modern means of emulation and debugging, it is equipped with integrated editors for visualization and configuration of data exchange.

How much is the best equipment worth? From 31,680 rubles.

- operator panel and programmable controller functions are combined in one housing;

- acceptable cost;

- guaranteed long service life;

- takes up little space in the automation cabinet;

- control algorithms and visualization are developed in one programming environment;

- the presence of a touch-sensitive resistor 7-inch display;

- it is possible to update projects and firmware;

- supports OWEN, Modbus, OPS UA exchange protocols;

- a huge number of communication interfaces;

- supports web visualization;

- equipped with an embedded Linux operating system;

- integrates with the OwenCloud cloud service;

- supports FTR and NTR protocols;

- boasts a highly configurable WatchDog timer.

- significant were not identified.

SPK110

If you are at a loss as to which product is better to buy, opt for this model. In the rating of high-quality products of this type, it occupies not the last place. Belongs to the category of inexpensive. A review of the SPK1xx line shows that this model is a product of its development and improvement. The set of interfaces is striking, as are the stated specifications. It can be used for most of the automated systems used in industry, healthcare, energy and housing and communal services.

What are the main differences between the model and similar designs of the same brand? We suggest that you familiarize yourself with the marked functionality and the declared settings:

- Runs on Linux platform (embedded version).

- For ease of use, the following interfaces are involved: 2 x RS - 232, 3 x RS - 485, USB Devise, Ethernet, USB Host, SD card dispute.

- Resistor display with a diagonal of 10.2 inches.

- The CODESYS V5SP11 Patch5 environment is used for programming.

- Support for NTP and FTP protocols.

- Each of the products in this line has a set of projects of the same size, which makes them fully compatible.

- The declared degree of protection is IP65.

- Web visualization support is acceptable.

- PLC and HMI function available.

- Support for such communication protocols as Aries, Ascii, RTU and TCP.

- The presence of a specific conductor (DB9 - terminals).

- Timer configurable.

- The input and output points can be extended.

As for programming, the device is equipped with advanced debugging and emulation tools, it is able to support five programming languages, there are no restrictions on the number of used variables and blocks.

Recommended scope of use:

- in housing and communal services;

- climatic equipment can be controlled;

- an integral part of the automated control system for water utilities;

- firms - manufacturers of building materials;

- in HVAC systems.

The product can be purchased at a price of 42,960 rubles and above.

- thanks to the device, the total cost of the control system is reduced;

- high quality;

- good value for money;

- long service life (at least 12 years);

- saves free installation space in the cabinet;

- a unified program for visualization and development of control algorithms.

- significant are not established.

For distribution systems

LSIT

Modern equipment, which has found application in many industrial sectors, thereby significantly facilitating the management process. For the convenience of using the installed interface and creating your own interaction algorithms, the free ScreenEditon environment is used. Today it is difficult to find industrial-scale enterprises that would not use such devices. The human-machine interface is extremely user-friendly. Equipped with a multifunctional Lsit panel, which allows it to be used in various industries.

Initially, the manufacturer assumed that such systems would become assistants in ventilation and air conditioning of premises. But practice has shown that it would be unreasonable and unpromising to be limited to these frameworks.

The wide functionality of the device in combination with the possibility of control by means of a sensor makes it possible to integrate the device into already used production processes. It is also possible to create new, modern and more efficient automated systems. With the help of such equipment, it is possible to establish the operation of a system of any type, including those intended for the control of technological processes or enterprise management.

This panel is a product of Russian production, which has been developed from scratch and brought to perfection. The design process took into account the advice of leading experts in this area, as well as the features of modern Russian production. This allowed the products to find themselves at any production facility, both small and significant in terms of capacity and volume of products, as well as its purpose.

Supports communication protocol of the standard type "Modbus", which establishes "communication" between industrial equipment and electronics. For a professional user, the appearance of the panel should not cause any difficulties. Easy-to-read pictures located in convenient places facilitate the prompt adjustment of equipment. There are various connection options, including CAN, Ethernet, USB, RS485, which allows you to quickly and without any problems get into work.

The intuitive interface is specially designed for this modification. Thanks to him, there is a wide visualization opportunity for managing working projects, as well as creating them.

The main technical characteristics are as follows:

- The product is produced in three modifications: SPK LSIT 05-400 with a five-inch version combined with input / output modules, SPK LSIT 10-400 (ten-inch), SPK LSIT 07-400 (seven-inch version).

- Mounted in a shield.

- Not afraid of explosive environments.

- Works at temperatures from 0 to +50 degrees.

The manufacturer offers customers a product at a price of 19,650 rubles.

- the presence of special software Screen editor for the operator panel allows developers to edit the user's screen from their computer;

- makes the work of the enterprise easier, safer and more productive;

- with her participation, management processes are under strict control;

- availability of modern industrial design;

- multifunctionality, which allows it to be used in almost all industrial sectors;

- high quality materials used in the manufacture, which minimizes the negative effects of external influences on the body, including ultraviolet radiation;

- excellent value for money;

- significant savings in free space;

- quick and easy installation;

- significantly reduces the cost of the system;

- the presence of two certificates of conformity (resistance to mechanical and climatic influences);

- all components interact in concert with each other.

- significant were not found.

Berghof EU 1000

Despite its compact size, it is quite a powerful device, and the range of interfaces is impressive. Programming environment - Codesys v3. To expand the inputs and outputs, they resort to using modules of the E-I / O line, which are connected via the internal bus directly to the PLC. Distinctive features of this model are as follows:

- The presence of a web server makes it possible to view the visualization through a standard Internet browser, and you can use any personal computer, tablet or phone.

- You don't have to think about how to configure it when connecting an expansion module. It is not necessary.

- EtherCatb RS - 232, Can, Ethernet built in.

- Able to support a large number of protocols.

- Information archiving takes place on SD - card or USB.

Main technical characteristics:

- power consumption - 7.2 W;

- RAM - 128 MB;

- voltage - 24 V;

- processor - 400 MHz;

- temperature range - from 0 to +55 degrees;

- weight - 150 g.

The device can be purchased at a price of 51,306 rubles.

- you can update the controller programs using an external USB drive;

- six programming languages (CFC, LD, ST, IL, SFC, FBD);

- convenient body parameters;

- EtherCat bus with high speed;

- easy to operate;

- long term of use;

- does not take up a lot of free space.

- absent.

Berghof EC 22 XX

A powerful controller with many outputs and inputs on board.In addition, there is an extended set of interfaces. Programming is done in Codesys V3, equipped with a built-in web server. With regard to technical characteristics, for the full operation of the device, you need a voltage of 24V, relative humidity - up to 85%, complete absence of condensation. Product dimensions - 210 x 106 x 48 mm, weight does not exceed 750 g, processor - 800 MHz.

The average cost is 64,964 rubles.

- supports 6 programming languages;

- compact device;

- there are 16 discrete inputs and outputs;

- RAM - 256 MB;

- works on OS Windows;

- an additional function is installed - a real time clock;

- supports many protocols;

- very powerful processor;

- high speed bus;

- reliable;

- the set of interfaces is significant;

- long service life.

- significant were not found.

ECC 21 00

The scope of the programmable logic controller is practically all industries. Designed for the automation of technological processes. The novelty belongs to the category of high-performance PLCs. The small case houses a powerful 800 MHz processor. It has a built-in set of outputs and inputs, expandable thanks to the E-I / O module.

Programming environment - Codesys V 3.5. The device is qualitatively distinguished by a large set of communication interfaces: RS 232, EtherCat, RS 485, Can, Ethernet. The visualization takes place thanks to a web server built into the PLC.

Possesses the following technical characteristics:

- weight - 550 g;

- temperature range - 0 - +55 degrees;

- humidity - up to 85%, condensation is not acceptable;

- dimensions - 95 x 128 x 46 mm;

- RAM - 256 MB;

- consumed current - 0.3 A;

- voltage - 24 V.

The average cost of a product is 52,339 rubles.

- small size;

- reliable;

- durable;

- easy to use;

- saves free space;

- sufficient power;

- easy and quick to install;

- lowers the cost of the system.

- significant are missing.

Conclusion

Touch panel controllers are widely used in various industries and housing and communal services. They differ in parameters, functionality, and performance, which is assessed according to the following criteria:

- industrial network bandwidth;

- time of command execution;

- the duration of the controller cycle;

- bus bandwidth;

- reaction time.

Before starting its work, the PLC loads the operating system and user programs ROM and RAM, conducts initial testing of the hardware. Main operating modes:

- debugging;

- step by step execution of the program;

- viewing;

- editing the values of variables;

- others.

If the devices are designed for responsible work, they are able to perform the following functions:

- check user programs;

- signal when the watchdog timer is triggered;

- detect memory failure;

- find errors in the central processor;

- detect a power outage;

- find an open or short circuit in the load and sensor circuit;

- understand that the fuse is out of order.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive medicines for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87681 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72463 -

Top rating of the best means for male potency in 2020 with a description

Views: 68296